-

0

Shop Cart

Waste Products

We have a lot of heavy duty machinery in our sawmill and warehouses at Nelson Butler Timber, some of these include planers, flatteners, resaws, bandsaws, sanders, ripsaws etc. All of these brilliant bits of equipment produce waste products, more specifically firewood and sawdust, and a lot of it. We don't let any of this go to 'waste', but instead prepare it to be sold and taken away by any who may find the use for it.

Firewood

Our large Stenner bandsaw is running almost everyday, Monday to Friday, eight o'clock to four thirty. This means a lot of logs are sawn through our mill, producing high quality beams and specialist through and through boards. On top of this our ripsaws and resaws run most days, working carefully to rip down smaller beams, slabs, boards etc. The result of these machines working in unison, day in and day out is not only the production of beams and boards but also quality firewood. We stack each piece of firewood into crates fresh off the saw, where they are then strapped up into large bundles and stacked away, awaiting the next customer. We sell softwood and hardwood bundles, hardwood being the more expensive option as oak burns slower. Even though softwood burns faster it is still a very worthy burning material to keep you warm in the winter. Bundles can range in length depending on the size of the logs being cut at the time but most bundles tend to be roughly from around 2.3 to 3.5 metres long.

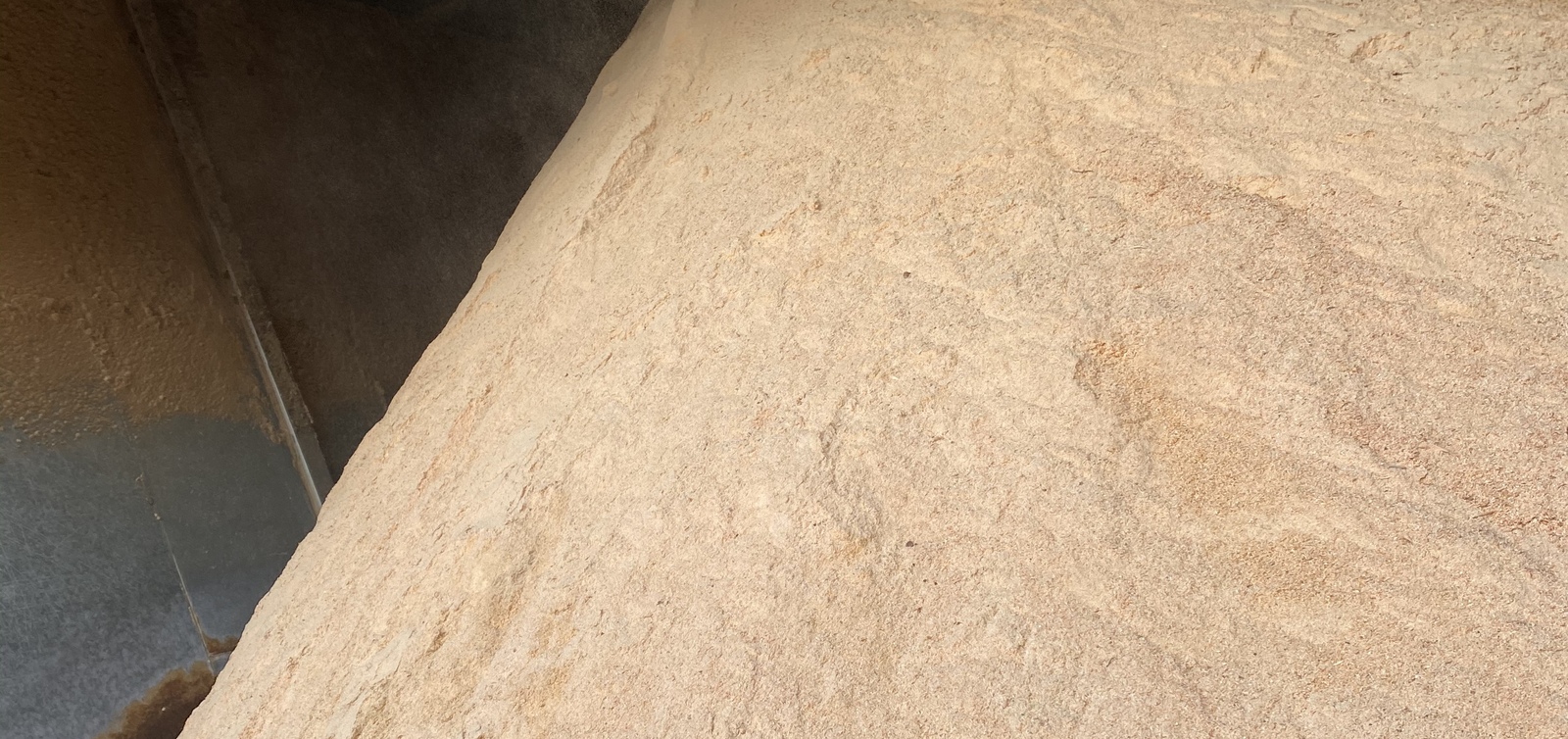

Sawdust

As well as firewood, our saws produce copious amounts of sawdust, and our other machines also contribute to this. We have sawdust extractors and tube networks inside our sawmill and workshops to keep on top of this. Although we do not dry the saw dust, we do keep in under shelter. It is available for purchase at any amount.